In the screen printing industry, color matching is the process where color swatches or samples are used to compare and match colors so that the product is precisely the right quality that the customer wants and needs. Here at ECI, we typically use the Pantone Color Matching System – a booklet of hundreds of color chips that we use to standardize each customer’s products and equate them with their unique ink mixing formulas. Color matching takes training, discipline and an understanding of everything that makes color look the way it does. There are many different factors and variables that effect color in screen printing and must be taken into account when designing a new part.

This article is the first of a series concerning variables that effect color matching.

The Material

The material or substrate that is printed on makes a difference in the color that is printed on it. There is color casting - a natural color in every substrate and it is nearly impossible to get a completely clear material to print on so this must be considered before choosing both a material and color.

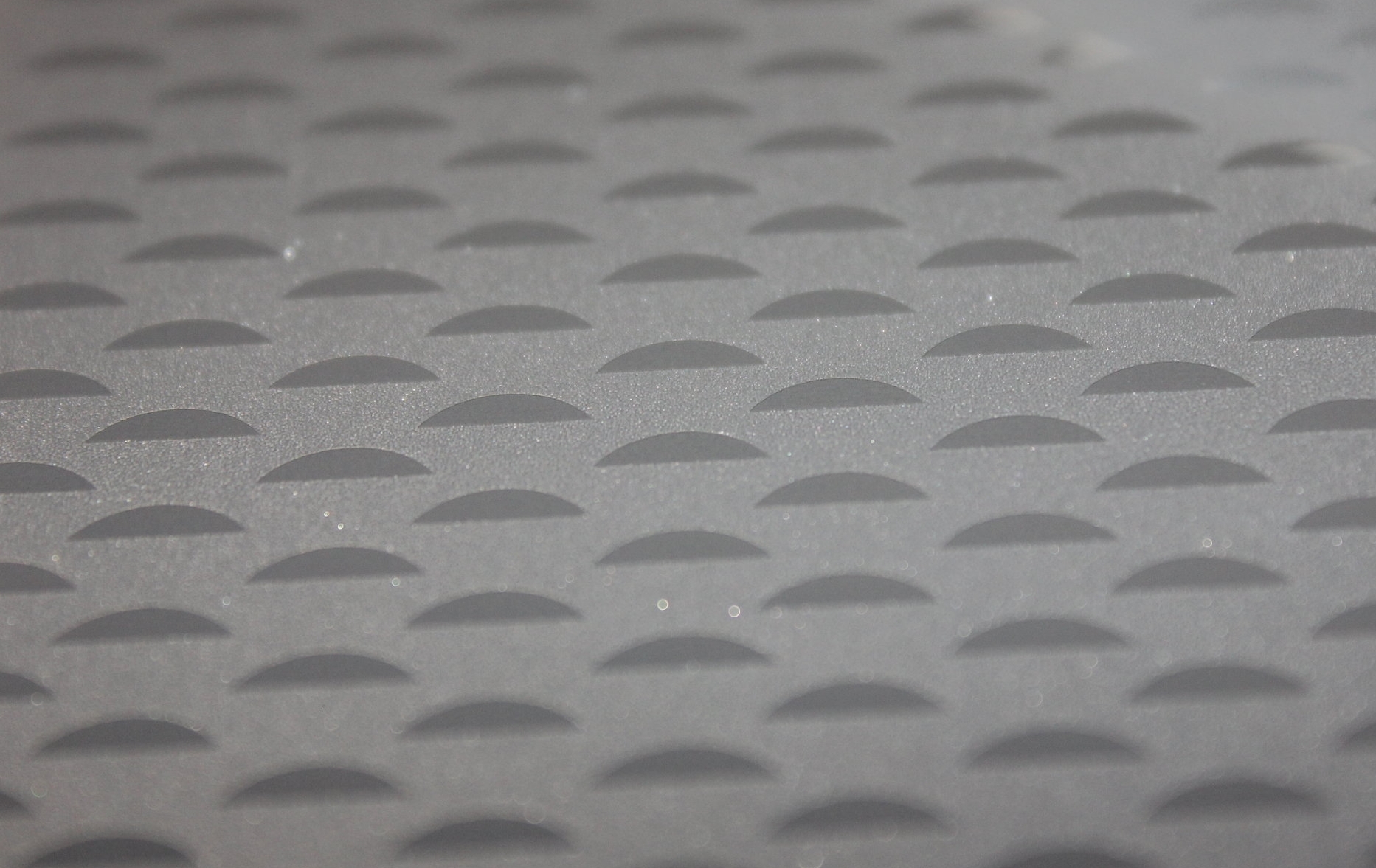

Here at ECI, we most commonly print on either polyesters or polycarbonates. Some polyesters are already very clear, but have a reflective quality about them. Meanwhile, there are other polyesters are textured with a natural yellow coloring. The same thing goes for polycarbonates – there are some that are very clear and others that are textured with a natural blue color. Different brands have different characteristics to keep in mind. Some materials are a solid color, such as white. White is a broad term and can come in many different shades, which also affects the color. This is a big consideration in the printing world, especially in digital printing.

ECI also prints on vinyl and 3M label stock which can either be matte, glossy or even come in different colors, all of which affect the appearance of the ink.

ECI prints on metal surfaces such as rolled steel, powder coated, aluminum, smooth anodized, raw metal, and brushed aluminum. Epoxy or enamel inks are used on these surfaces and can be affected by the different metal surfaces depending on their color and texture. Metals like brushed aluminum will have a metallic surface which changes the appearance of the ink, especially opaque colors.

Both of the color swatches shown above show the same color. However, the one on the right has a white back flood while the swatch on the left does not. Notice that the swatch on the left is slightly transparent because the ink has no backing to it. The colors themselves look drastically different as the swatch with the white backer flood looks more vibrant.

Inks can also either be printed on the front or back of the material. By printing on the backside of the material, it would have to be taken into account the effect of the substrate’s natural color and the texture of the material, which will dull the color and either give it a matte or glossy finish. Even printing on the front of the material, the color of the ink can be affected, particularly if it is slightly transparent. The material, adhesive and liners can be seen through the material and the ink as well, affecting the overall look of the product. It is really what the ink is set on that matters most, as it will have the biggest effect on the color.

This Pantone booklet shows a matte finish, which was offset printed on paper, while the overlay uses the same color screen printed on plastic. To the trained eye, the colors are different - but still use the same formula. The cause for the difference in color: the material.

In the screen printing industry, we use the Pantone Color Matching System as a guide and follow it as closely as possible. However, the Pantone books are offset printed on paper while ECI screen prints on plastics, second surface, with textures and finishes. As discussed earlier in this article, material makes a difference in the appearance of the color and therefore, makes color matching a more challenging feat than at first glance.

Next article: How color effects color matching.